High-end aluminum alloy materials And deep process

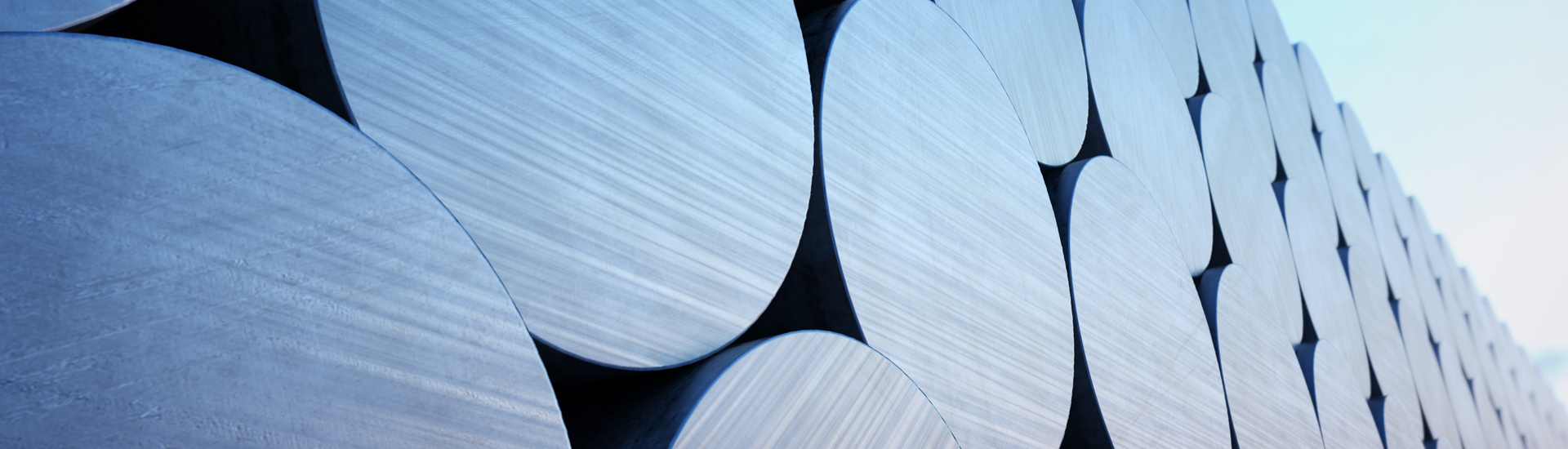

The 200,000-ton high-tech aluminum alloy material project of Mengtai uses molten aluminum produced by Mengtai Aluminum as the main raw material, and mainly produces high-end aluminum alloy materials and blanks that replace imported materials. The products are widely used in the fields of automobile manufacturing, rail transit, electronic products, etc.. The project was invested and constructed in 2019 and is located in the Dalat Economic Development Zone. The first phase of 100,000 tons was completed and put into production at the end of the year, and 8 casting production lines and auxiliary facilities were built.

The project design adopts American wagstaff casting equipment, American snif online degassing device, French Ifer homogenizing furnace and industry-leading tilting resistance heating furnace, and has reached the advanced level of the same industry in terms of equipment selection, process technology, safety and environmental protection, etc. . After the project reaches full production, the annual output value can reach 5 billion yuan, and nearly 1,000 people will be employed.

The development of high-tech aluminum alloy material projects is an important strategic choice for the company, and it is also the only way for the company's aluminum industry to enter the high-end field. The project will effectively promote the transformation and upgrading of enterprises and high-quality development, further promote the extension of the regional industrial chain and the increase of industrial added value, and effectively promote the development of the local economy.

Production line

Cast Rod Products